Running an established business comes with an age-old conundrum – how do you grow without hitting bottlenecks?

Studying successful business process improvement examples and optimising your operations is crucial, but there are common challenges along the way, such as:

- Unclear vision and planning, which make improvements hard to implement.

- Scaling challenges, like managing multiple suppliers and locations with complex logistics.

- Cash flow constraints, where the lack of fast, accessible funding hampers process improvements.

The key is to learn from these business process examples and create a clear road map to eliminate inefficiencies and drive growth.

This guide will help you do just that. We’ll walk you through six case study examples of business process improvement and highlight actionable strategies including:

- Optimising shipping processes

- Investing in better inventory management

- Improving internal and external communication channels

- Making the best use of data

- Smoothing out compliance processes

- Investing in AI to future-proof your business processes

6 Business Process Improvement Examples That Can Help You Scale Faster

The best business process improvement examples are those that allow you to make multiple improvements at once, be it streamlining operations, making customers happier, or simply putting your business on the path to higher profits.

Here are six examples that can help your business tap into a myriad process improvements.

1. Optimise shipping processes to prevent costly errors

Shipping is a delicate part of business operations that, if disrupted, can damage customer relationships and threaten profitability.

Unfortunately, many businesses suffer from shipping bottlenecks caused by human error or manual inefficiencies to the point that fixing these mistakes can even become a competitive advantage.

Automated systems and tools are now playing a big role in cutting down on these expensive mistakes, reducing overhead costs and time wasted.

The problem

Let’s take the example of a large e-commerce retailer that ships thousands of customer orders every day, including high-demand, time-sensitive products such as electronics and fashion.

In one instance, a bulk order of premium smartphones was accidentally shipped to the wrong region, causing long delays and customer complaints. The retailer had a last-minute marketing campaign tied to the release of the product and customers expected their phones on the launch date.

Due to the wrong shipment destination, the phones arrived late, causing lost sales, damaged customer relationships and costly expedited shipping to correct the error.

The business process improvement

This example highlights the lack of automatic address validation within the retailer’s order management system.

Instant and automatic, this technology checks shipping addresses against a global address database in real-time. It flags discrepancies before the shipment even leaves the warehouse.

Businesses can also add an extra layer of security with a quality control check, where a second team verifies high-priority or time-sensitive orders before dispatch.

A proactive customer notification system, where customers receive real-time updates and tracking information, can also help manage expectations and improve customer satisfaction, even when issues arise.

2. Invest in better inventory management

Poor inventory management causes ‘profit erosion’, a handy term to refer to the gradual build-up of small wasteful actions that slowly eat away at your cash flow and bottom line.

Stock-outs cost global retailers almost $1 trillion (R18 trillion) annually, according to a recent Harvard Business Review article, and poor inventory management is at the root of it.

Many existing processes are blighted by tracking errors and stock replenishment gaps that lead to these losses. Without a clear understanding of your warehouse inventory, you risk overselling, underselling or allowing stock to become obsolete.

The problem

An electronics distributor faces frequent stock-outs and overselling due to poor inventory visibility.

Warehouse staff rely on manual checks to track the availability of high-demand components like circuit boards and screens. Errors in stock data lead to delayed shipments and missed sales.

For example, a customer places a large order for a popular laptop model, only to learn it was out of stock after payment was processed.

Meanwhile, obsolete models are overstocked, tying up cash flow. The inefficiencies in their inventory process are eroding profits and damaging customer relationships.

The business process improvement

Centralisation is key. Warehouse workers, managers and senior leadership must all work from the same real-time inventory database and a smart inventory system is the core ingredient of this, especially if your company has recently undergone warehouse expansion.

Management tools like Zoho and Fishbowl provide a centralised hub that lets teams track stock movements, automate replenishment and gain visibility into supply chain operations. With everyone singing from the same hymn sheet, there’s a much lower risk of duplicate processing or missed shipments.

Smart inventory management systems are helping not just to avoid stock-outs, but to make the most of high-stock periods.

A study mentioned in the above Harvard report found that notifying customers of high-stock delivery windows led to a 4.6% increase in average daily spending: it also reduced stockout-related refunds and replacements by 2.2% and 2.7%, respectively.

3. Improve internal and external communication channels

The larger a company becomes, the easier it is to muddle communication channels, both inside and outside the organisation.

Internally, miscommunication not only disrupts worker morale, but also negatively impacts the customer experience as employees may provide incorrect information, fail to meet expectations, or cause delays in fulfilling orders.

Externally, of course, customer satisfaction will also plummet if support communication channels are inefficient and time-consuming.

The problem

A manufacturing company with a growing workforce and multiple production teams faces internal communication challenges.

The production team often struggles to communicate material shortages or production delays to the scheduling department, causing a ripple effect where customers receive late deliveries. In one case, a customer was promised a delivery date, but owing to a lack of communication between departments, the production team was unable to meet the deadline.

The customer was left dissatisfied, the company lost revenue and also suffered a tarnished reputation.

The business process improvement

Introduce an integrated communication platform that connects all departments, such as an enterprise resource planning (ERP) system or a company intranet. This keeps all departments (from manufacturing processes to customer services) aligned on timelines and resource availability. However, you may need more than one tool depending on the size of your organisation.

“Recognise that multiple audiences may exist within your organisation, each with different preferences for communication, so several tools might be needed,” says Rob Forrester, president of communication experts, Guardians Agency in a Forbes article.

Externally, it’s all about customer support workflows. This includes creating clear communication channels, like dedicated email support and live chat and using them to provide regular updates to customers.

4. Make the best use of your data

Data forms the backbone of continuous process improvement, but many companies don’t use it correctly.

Low data quality is a serious problem that often mutates into several damaging consequences, ranging from missed growth opportunities to a lack of compliance.

Companies even become known for this, with employees and customers picking up on inconsistencies and errors in data-driven decisions or communications.

The problem

A global logistics company struggling with data quality issues in its inventory and shipment tracking system faces big operational challenges.

Inconsistent data entry and a lack of centralised reporting mean the company experiences shipment delays, inaccurate stock levels and frequent errors in order fulfillment.

Employees waste time searching for the correct information, and customers often receive incorrect delivery updates or wrong inventory status.

As a result, the company is missing out on growth opportunities, facing compliance issues and suffering from a tarnished reputation in the market.

The business process improvement

Implementing a data-driven methodology like Six Sigma comes with two big data-related benefits: improved data quality and a huge reduction in process defects.

For data quality, for example, Six Sigma helps with streamlining data collection processes and uses statistical tools to analyse data and identify and resolve inconsistencies. It even provides up-to-the-minute reports so managers can carry out informed decision-making in a fraction of the time.

Other methodologies that can help upgrade data processes include Total Quality Management (TQM), Lean, Kaizen and BPM. Each have their own process improvement methodologies that many organisations swear by.

BPM aligns business processes with data flow, making it easier to monitor and improve data quality across the organisation.

TQM, for example, focuses on continuous improvement with employee involvement. Lean and Kaizen work by optimising processes via waste reduction.

Together or individually, these tools can transform data handling so that you can improve operations and strengthen your market reputation.

5. Smooth out compliance processes

Compliance is a minefield for businesses, and getting the organisation ready for audits is extremely complicated without a highly efficient process in place.

Many organisations lack centralised systems that excel in standardising processes to make compliance easier. This includes team member templates to follow, and clear approval processes.

The problem

A large global financial services company faces compliance challenges across its international branches.

The absence of a centralised system for tracking regulatory requirements leads to inconsistent reporting and missed deadlines for filings in different jurisdictions. Each office uses its own templates, which causes discrepancies in data submission.

These compliance gaps expose the company to the risk of heavy fines and a tarnished reputation with regulatory bodies.

The business process improvement

Business process management software helps to standardise processes and keep all branches on the same page.

It uses KPIs to monitor compliance deadlines and creates clear approval processes, so that the company can easily see if every office adheres to the same set of compliance standards.

Process mapping helps visualise and keep regulatory requirements on the same page across regions, while employee engagement initiatives help familiarise staff with new compliance procedures, especially during the onboarding process.

The result? Much improved operational efficiency for compliance, which ultimately improves the company’s standing with regulators.

6. Invest in AI to future-proof your business processes

Artificial intelligence is reshaping the foundation of how businesses operate. While traditional methods like Lean, Six Sigma and Agile have driven incremental improvement efforts, AI offers a chance to redesign processes from the ground up, not just add enhancements.

Current tools, like those mentioned above, have helped with refinement, but still rely heavily on manual input and are often limited in scalability. AI-powered features are set to change this.

The problem

A healthcare provider that has always relied on manual processes and siloed systems for patient records has used process improvement methodologies like Six Sigma to improve certain aspects of its operations. However, it still depends heavily on human input for data analysis and decision-making.

Despite past improvement initiatives, the provider still faces challenges in scaling services efficiently due to manual processes that result in delays, errors and higher costs.

The company’s leaders know that automation and AI will improve their processes and outputs, but the cost of investing in it is very high, with expensive set-up and staff training adding to the costs.

The issue is restricting future process improvement projects and holding the provider back from competing in a challenging market.

The business process improvement

With limited in-house capital available to invest in long-term process automation improvements, the provider must look elsewhere for funding.

Like any business that needs funding, alternative financing options that offer quick access to capital may be the best way for them to bridge the AI gap.

A funding solution like Lula’s Cash Flow Facility ticks all the boxes. After a quick and easy online application process, the provider can get quick access to up to R5 million in funding. With no reapplication required (subject to affordability), they only pay for what they use and can easily request more funds for future improvements, if needed.

Armed with the capital to invest in automation, the provider can now offer a more streamlined, cost-effective healthcare service that can scale quickly and improve patient outcomes.

How Can Business Processes be Improved?

5 Actions to Take Right Now

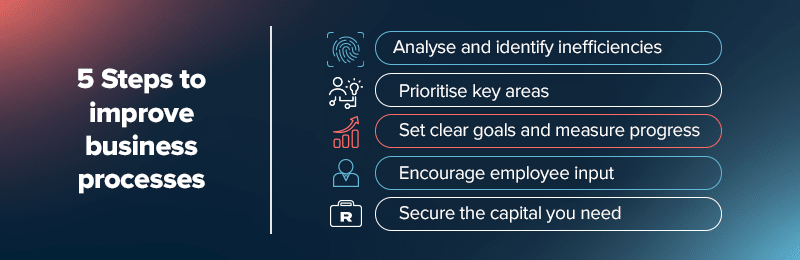

The business process improvement examples mentioned earlier, work best as a part of a strategic approach to boost efficiency and productivity. However, you can make some meaningful improvements right away, including:

- Analysing and identifying inefficiencies: Map out your current processes and pinpoint bottlenecks or redundant steps.

- Prioritising key areas: Focus on high-impact areas like inventory management or customer onboarding for faster results.

- Setting clear goals and measuring progress: Track key metrics to ensure your process improvements are driving the right outcomes.

- Encouraging employee input: The aim is to develop a culture of feedback to continuously adapt and optimise.

- Securing a source of fast funding: Setting up a financial reserve, like Lula’s Cash Flow Facility, will ensure you have the means to invest in improvements right away.

By taking these steps, you can create a more streamlined, efficient business that’s ready to scale.

Don’t let a lack of funding bring your business processes to a halt. Apply for business funding today and get access to up to R5 million within as little as 24 hours.